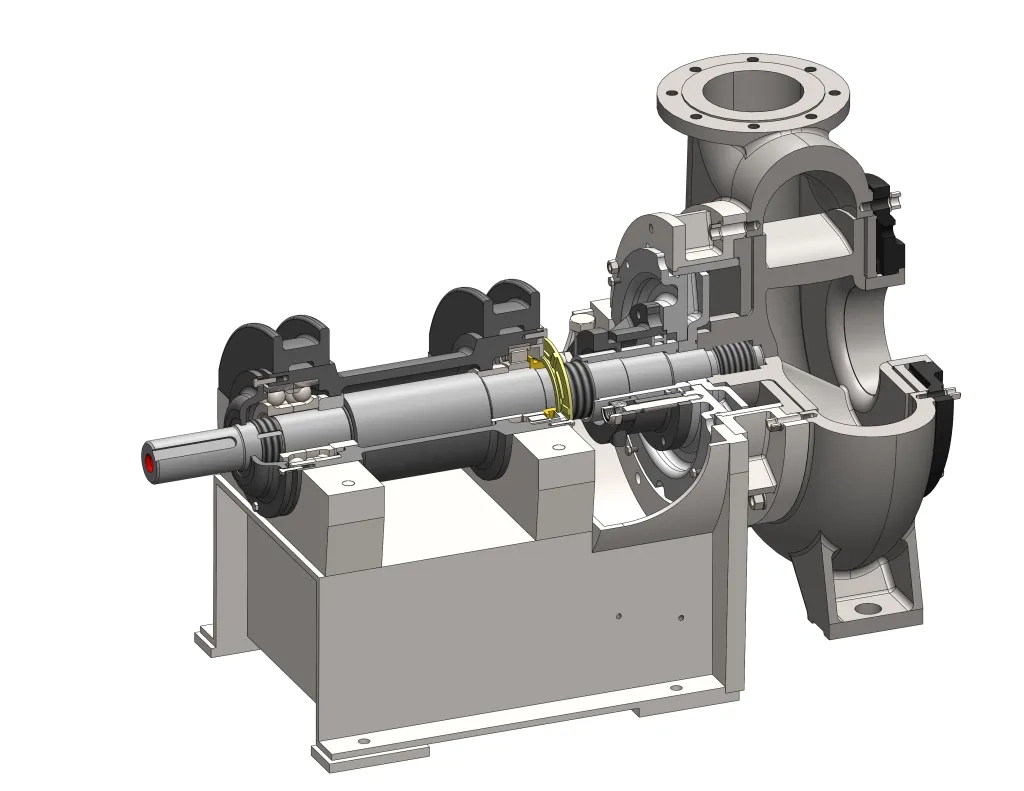

In three different pump sizes (NPK 80, NPK 125 and KBK 200), they convey comminuted, hot meat-bone-fat mixtures. In the process, the water content is reduced with the help of evaporation. The end product: protein meals and fats from animal by-products of the so-called category 3.

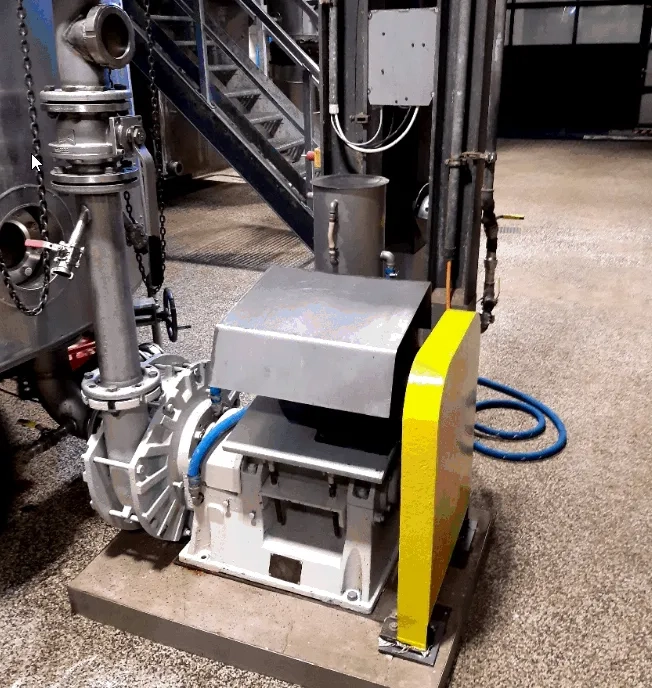

Compared to other pumps, a general overhaul was necessary this year after 30 years of operation. After the pumps had been in operation almost continuously for all these years, the KBK pump housing had to be replaced. The corresponding pump housing was already in stock as a spare part (more than 20 years).

trabajadores cualificados empleados en Habermann Aurum

que habla nuestra empresa para servir a todos los continentes

vida útil media de las bombas de lodo Habermann

es la bomba más antigua de la fábrica

donde nuestras bombas se utilizan a diariamente

como fabricante líder de bombas centrífugas en Alemania

¿Por qué bombas Habermann Aurum?

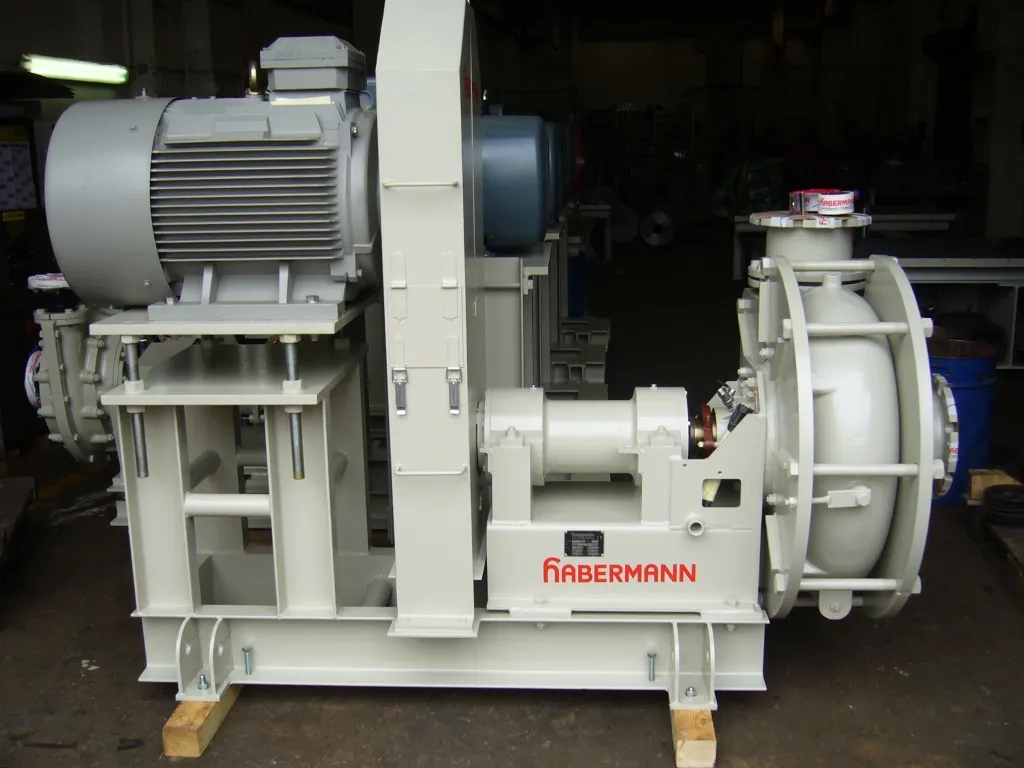

Habermann Aurum Pumpen es uno de los fabricantes líderes de bombas giratorias para el transporte de líquidos cargados de sólidos. Con casi 100 años de experiencia y la experiencia de más de 30. 000 bombas utilizadas en todo el mundo en una amplia gama de sectores industriales, nos hemos convertido en parte del sistema económico global. Nuestra cartera de productos incluye las áreas de bombas y válvulas. Gracias a la ingeniería interna, también somos capaces de resolver tareas técnicamente exigentes y complejas. Nuestro objetivo fundamental es desarrollar las bombas industriales más duraderas y sostenibles combinando décadas de experiencia con la tecnología más avanzada. Nuestras bombas se utilizan en la minería y la minería, la extracción de materias primas y energía, la siderurgia, la química, la industria de pigmentos, la perforación de túneles y la construcción especializada.

+49 234 / 893570-0

+49 234 / 893570-0 info@aurumpumpen.de

info@aurumpumpen.de