Wherever the highest abrasive wear duties are expected, the metallic centrifugal pumps of types KB, KBK, KBH or KBKM is the right choice.

The compact pump model of KB series has been developed for challenging operating conditions in tunnel construction and special civil engineering with a rough operating environment and restricted installation conditions.

The compact design of our high-performance and highly wear-resistant pumps in the KB, KBK and KBKT model series are customised for use as a supply pump or a feed pump in conditions with limited space in micro tunnel construction and pipe jacking.

The extra thick walls of the pump in the KB series easily withstand the stress from sliding abrasion in case of fine solid particles, as well as the impact stress caused by a high content of coarse particles.

The pumps with pressure nozzles of DN 100, 125, 150 and 200 nominal size are available for diverse applications. Low installation heights, highly wear-resistant materials and shaft seals with an expeller, a so-called relief impeller, or our self-developed HGD mechanical seal ensure safe use and peak performance in micro-tunnelling AVN machines for automatic pipe jacking with slurry-circuit.

Main features of KB model series:

- Easy maintenance

- Easy adjustable suction gap

- Strongly dimensioned closed impellers, pump housing and wear plates

- Generously dimensioned extra thick walls providing extreme high impact resistance, as well as the best performance even with a high content of coarse particles in the pumping suspension.

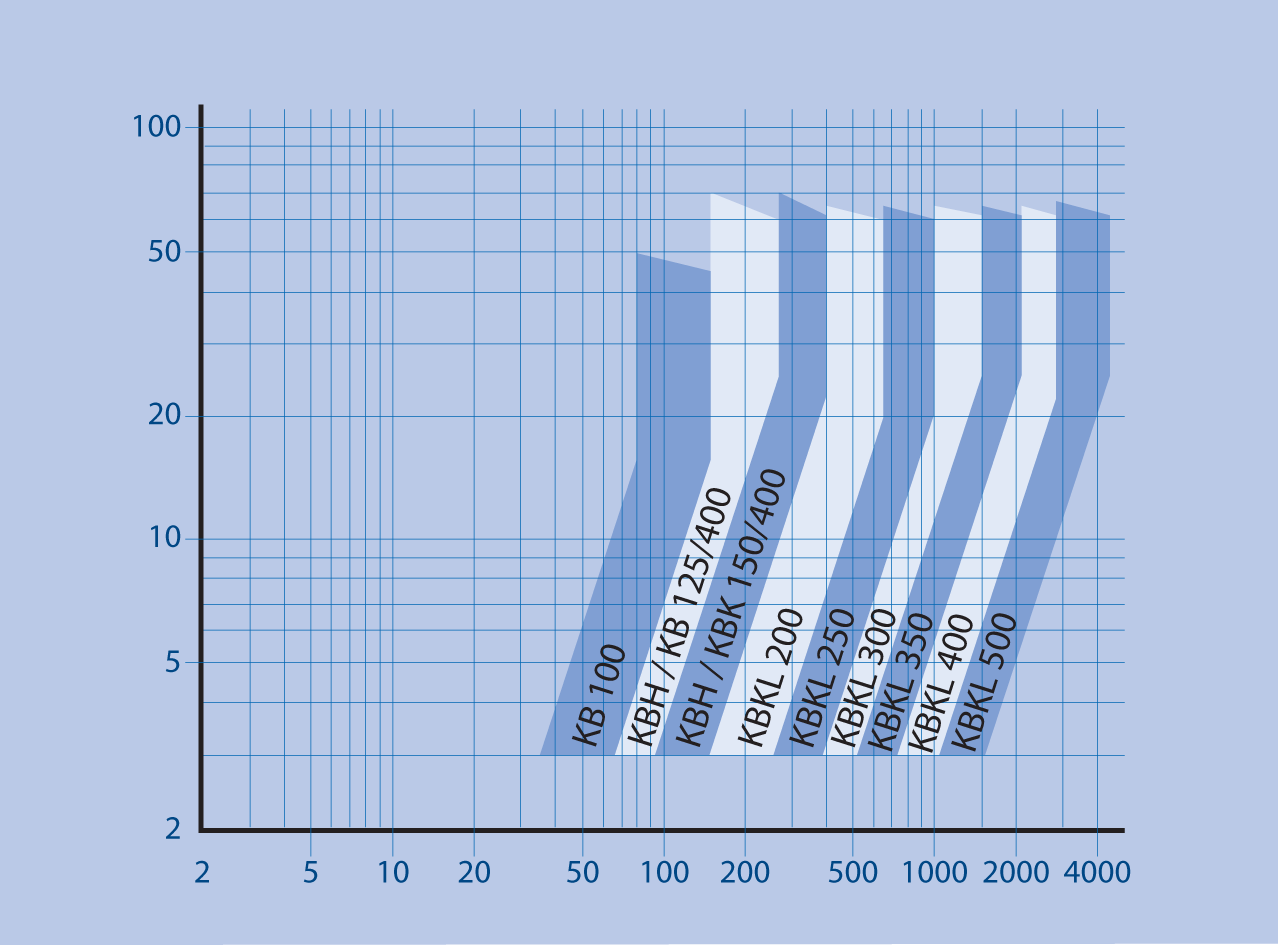

| Pumping flow | up to 5000 m3/h |

| Pumping height, single-stage | up to 85 M.FL.S |

| Pump rotational speed | up to 2000 min-1 |

| Connection nominal width | 100 - 500 |

| Maximum operating pressure | 16 Bar |

| Normal suction | 8 MW.S. |

| Pressure nozzle position | step by step |

| Corrosion-resistance with PH | 3 - 14 |

Сontact us We are here for you to advice regarding all questions about pumping technology. Having analysed your application characteristics, we will develop an appropriate solution for you. Contact us!

+49 234 893 570 0

+49 234 893 570 0 sales@aurumpumpen.de

sales@aurumpumpen.de