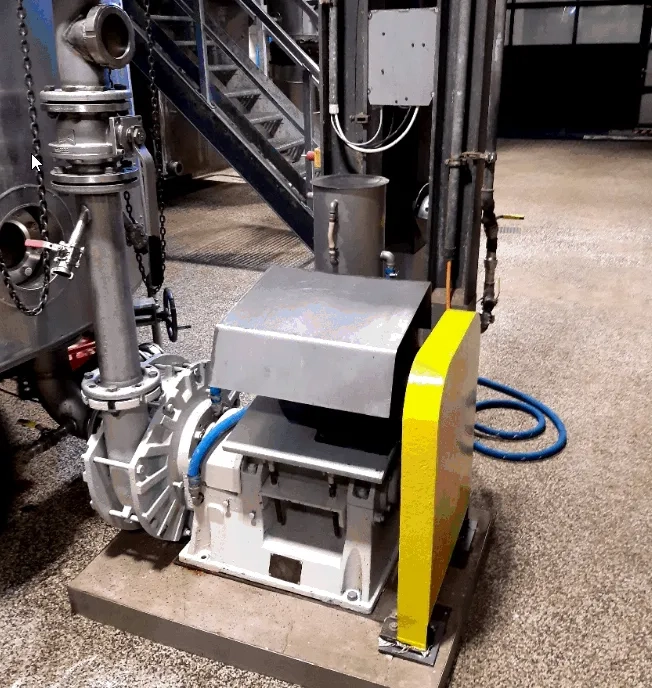

In three different pump sizes (NPK 80, NPK 125 and KBK 200), they convey comminuted, hot meat-bone-fat mixtures. In the process, the water content is reduced with the help of evaporation. The end product: protein meals and fats from animal by-products of the so-called category 3.

Compared to other pumps, a general overhaul was necessary this year after 30 years of operation. After the pumps had been in operation almost continuously for all these years, the KBK pump housing had to be replaced. The corresponding pump housing was already in stock as a spare part (more than 20 years).

Working for Habermann Aurum Group

Our company speaks to serve all continents

Average lifetime of Habermann slurry pumps

is the oldest running pump in the factory

Where our pumps are in daily use

We are one of Germany's leading manufacturers of centrifugal pumps

Why Habermann Aurum Pumpen?

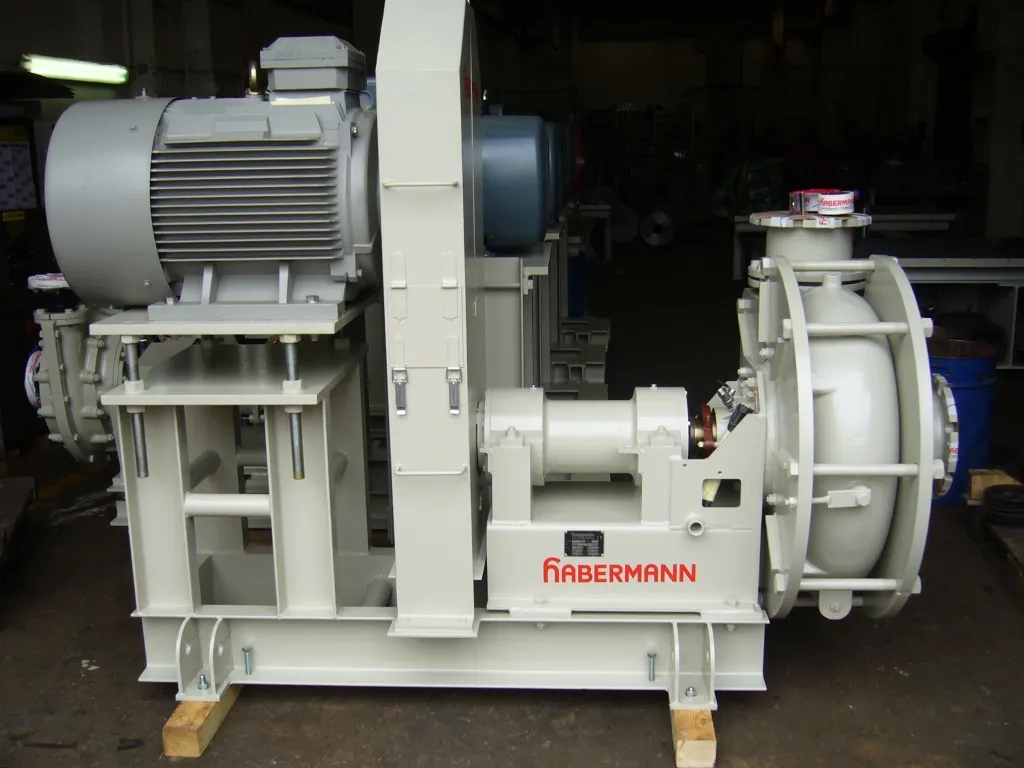

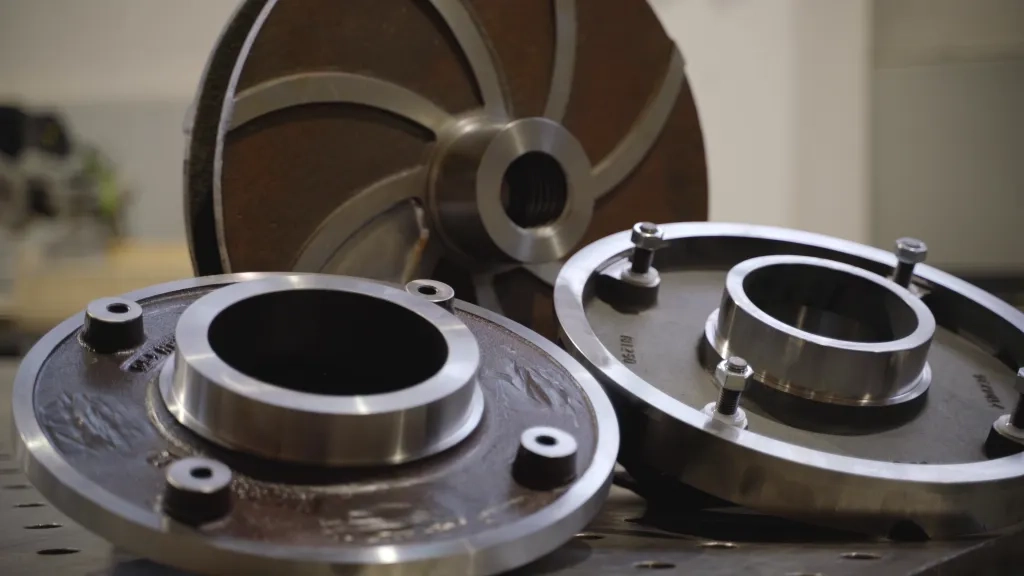

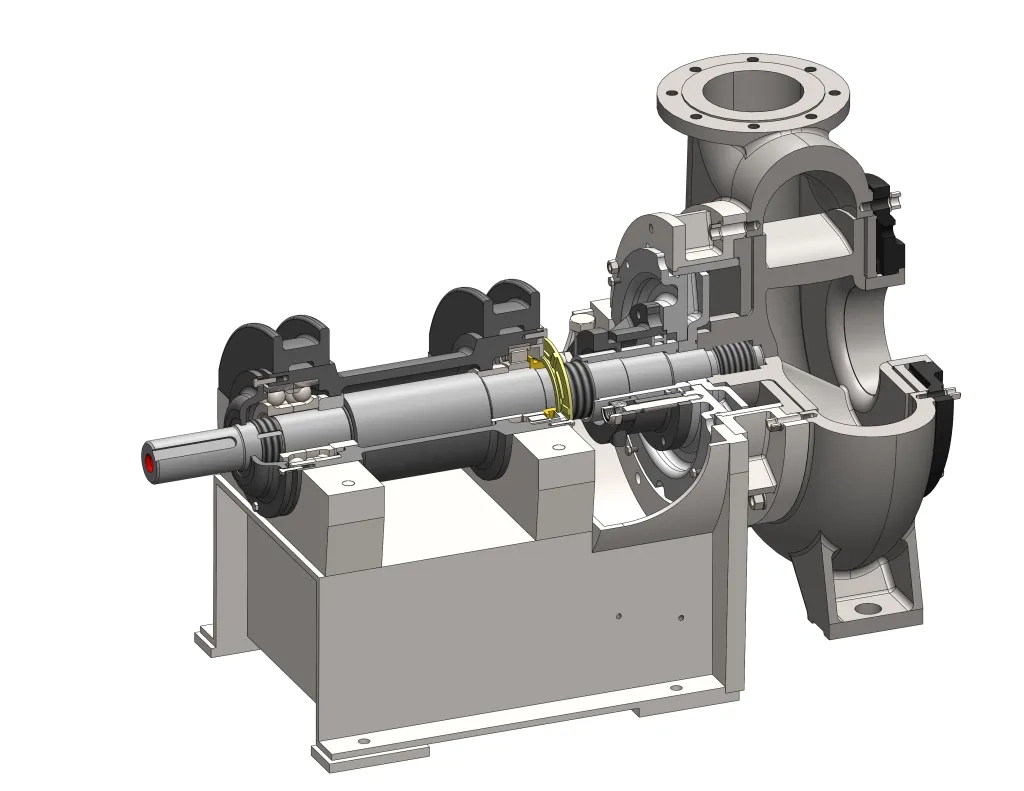

Habermann Aurum Pumpen is one of the leading manufacturers of centrifugal pumps for handling solids-laden liquids. With almost 100 years of experience and an expertise of over 30,000 pumps in use worldwide in a wide range of industrial sectors, we have become part of the global economic system. Our product portfolio includes pumps and valves. Thanks to our in-house engineering, we are also able to solve technically demanding and complex tasks. Our fundamental goal is to develop the most durable and sustainable industrial pumps by combining decades of experience with the latest technology. Our pumps are used in mining and the mineral industry, raw material extraction and the energy industry, the steel industry, chemicals, pigment industry, tunnelling and special civil engineering.

+49 234 / 893570-0

+49 234 / 893570-0 info@aurumpumpen.de

info@aurumpumpen.de