The construction of a new wastewater treatment plant in Atyrau is in full swing. With the commissioning of the new facility, the issue of wastewater treatment will be addressed, and the environmental situation in the region will be improved. The incoming wastewater will undergo a technological process that will bring it to a suitable level for various purposes.

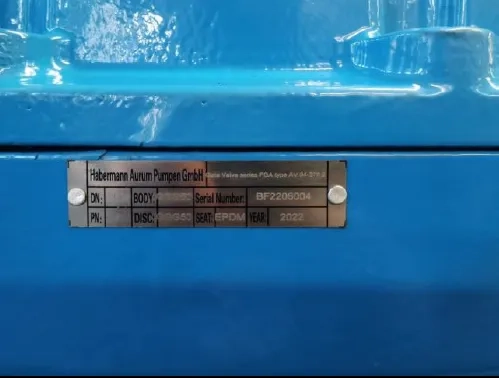

Our company was able to secure the project "Construction of wastewater systems, wastewater treatment plants, and pumping stations" in the right bank area of Atyrau due to its technical expertise and the competence of its professionals. This project involves the supply of various types of control valves, including manual, pneumatic, and electric actuators. We take pride in this achievement and are excited to contribute to the development of the city's infrastructure.

Working for Habermann Aurum Group

Our company speaks to serve all continents

Average lifetime of Habermann slurry pumps

is the oldest running pump in the factory

Where our pumps are in daily use

We are one of Germany's leading manufacturers of centrifugal pumps

Why Habermann Aurum Pumpen?

Habermann Aurum Pumpen is one of the leading manufacturers of centrifugal pumps for handling solids-laden liquids. With almost 100 years of experience and an expertise of over 30,000 pumps in use worldwide in a wide range of industrial sectors, we have become part of the global economic system. Our product portfolio includes pumps and valves. Thanks to our in-house engineering, we are also able to solve technically demanding and complex tasks. Our fundamental goal is to develop the most durable and sustainable industrial pumps by combining decades of experience with the latest technology. Our pumps are used in mining and the mineral industry, raw material extraction and the energy industry, the steel industry, chemicals, pigment industry, tunnelling and special civil engineering.

+49 234 / 893570-0

+49 234 / 893570-0 info@aurumpumpen.de

info@aurumpumpen.de