In tunnel construction and specialist civil engineering, we enjoy an excellent reputation worldwide and are the first choice for mechanical engineering equipment.

Description

In tunnel construction and specialist civil engineering, we enjoy an excellent reputation worldwide and are the first choice for mechanical engineering equipment.

Processes

Aerated concrete

Bentonite, cement batching

Micro-tunnel construction

Transport concrete

Vertical bores (land and sea)

Sand & gravel

Sand industry

Chalk slurries

Slate, marble, granite

Kaolin, clay

Cyclone feed

Civil engineering - diaphragm wall milling

Excavator works (ports, rivers)

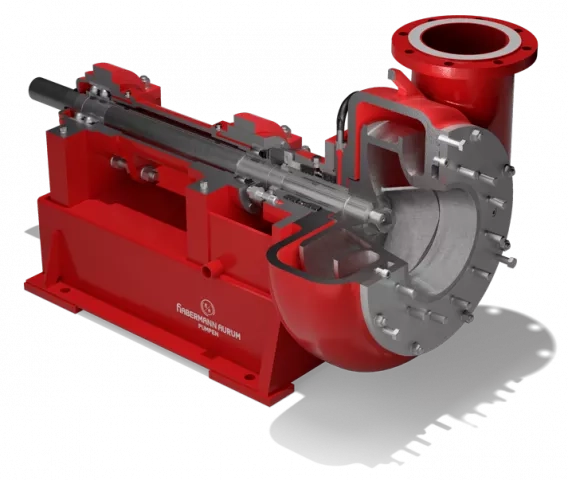

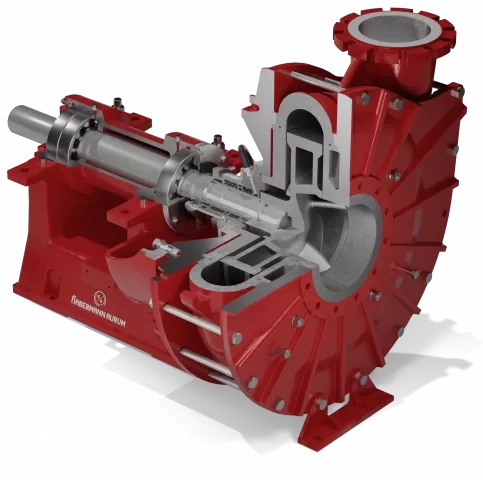

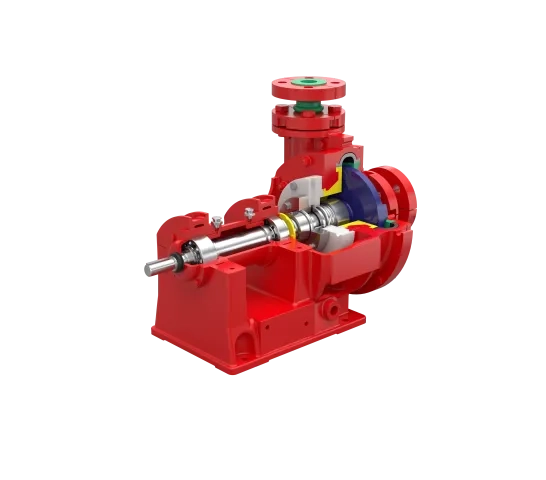

Series HPK Pump with CeramCarbide® coating Highly wear-resistant slurry pump with polymer cast lining

Series HPK Pump with CeramCarbide® coating Highly wear-resistant slurry pump with polymer cast lining  RPL-Serie Armored pumps for medium and heavy-duty applications Ideal for solid-laden media with a density of up to 1.5.

RPL-Serie Armored pumps for medium and heavy-duty applications Ideal for solid-laden media with a density of up to 1.5.  Heracles Submersible pump Heavy duty slurry pump

Heracles Submersible pump Heavy duty slurry pump  ELEVARO Agitator pumps High performance pumps for water-sand-slurry mixtures

ELEVARO Agitator pumps High performance pumps for water-sand-slurry mixtures  APNO Drainage pumps Reliable pumps for continuous industrial operation

APNO Drainage pumps Reliable pumps for continuous industrial operation  SENTINO Residual water pumps Pumps for construction and municipal application

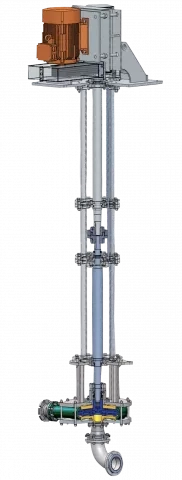

SENTINO Residual water pumps Pumps for construction and municipal application  Series V1/V2 Vertical centrifugal pump with long shaft Slurry pump with long or double shaft and intermediate bearing

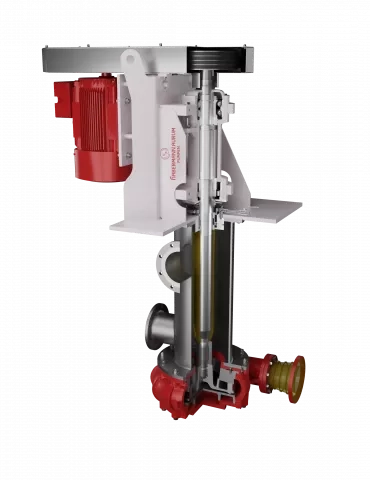

Series V1/V2 Vertical centrifugal pump with long shaft Slurry pump with long or double shaft and intermediate bearing  Series V330 Vertical slurry pump for dry installation Seal-less vertical pump with open system and own inlet pipe

Series V330 Vertical slurry pump for dry installation Seal-less vertical pump with open system and own inlet pipe  Series V300/V320/V340 Vertical pump for wet installation With mechanical seal, up to 5 m diving depth

Series V300/V320/V340 Vertical pump for wet installation With mechanical seal, up to 5 m diving depth  Challenger Series CRM/CRP Submersible pump for middle wear Submersible slurry pump as fully metallic or with elastic lining of hydraulic parts

Challenger Series CRM/CRP Submersible pump for middle wear Submersible slurry pump as fully metallic or with elastic lining of hydraulic parts  Series N Sump pump Seal-less armoured pump with its own pump sump

Series N Sump pump Seal-less armoured pump with its own pump sump  Series KB Dredging pump Excavator pumps for tunnel construction and special civil engineering

Series KB Dredging pump Excavator pumps for tunnel construction and special civil engineering  Series NPW Metallic pumps for industrial slurries Ideal for industrial slurry handling

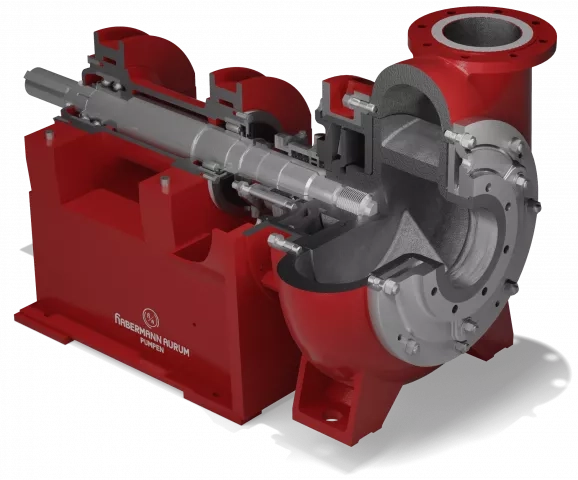

Series NPW Metallic pumps for industrial slurries Ideal for industrial slurry handling  Series NPK Highly robust pumps for slurry and solids Heavy-duty pumps made of highly wear-resistant casting material

Series NPK Highly robust pumps for slurry and solids Heavy-duty pumps made of highly wear-resistant casting material  Series HPK Slurry pumps with elastic lining Pump with elastic lining of all hydraulic parts getting into contact with the medium

Series HPK Slurry pumps with elastic lining Pump with elastic lining of all hydraulic parts getting into contact with the medium  ADST-600E Dredger ADST-600E With electric Heracles submersible pump type 250/580, flow rate up to 720 m3/h and head up to 40 m

ADST-600E Dredger ADST-600E With electric Heracles submersible pump type 250/580, flow rate up to 720 m3/h and head up to 40 m  ADST-400E Dredger ADST-400E Dredger with submersible dredge pump Heracles with the capacity by pulp reaching 400 m3/h, while the output by soil is not less than 100 m3/h, at the head of up to 30 m.w.c.

ADST-400E Dredger ADST-400E Dredger with submersible dredge pump Heracles with the capacity by pulp reaching 400 m3/h, while the output by soil is not less than 100 m3/h, at the head of up to 30 m.w.c.

Projects

Contacts

Сontact us We are here for you to advice regarding all questions about pumping technology. Having analysed your application characteristics, we will develop an appropriate solution for you. Contact us!

Subscribe to newsletter

Subscribe to our newsletter and receive the most important news about pumps, valves and services conveniently by e-mail in your mailbox.

+49 234 893 570 0

+49 234 893 570 0 sales@aurumpumpen.de

sales@aurumpumpen.de